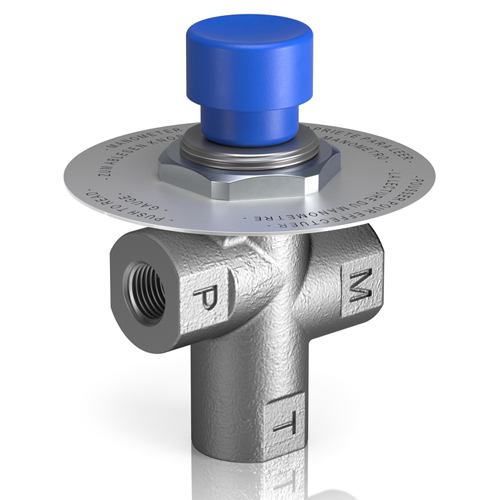

In normal condition fluid is completely isolated from the gauge until the knob is pressed. By pressing the knob fluid is connected directly from pressure port P to gauge port G giving instant and accurate reading on the gauge or the manometer. As the knob is released the spring loaded spool closes the pressure port automatically connecting the gauge port G to drain port T. In operation an orifice (0.8mm dia.) in Gauge Port acts as partial snubber, protecting the gauge from damaging pressure surge of fluid as the knob is pressed.